Compared with other methods of mechanical processing and plastic processing, stamping has many unique advantages both technically and economically.

The main performance is as follows:

(1) The stamping process has high production efficiency, convenient operation and easy realization of mechanization and automation. This is because stamping is accomplished by means of die and punching equipment. The number of strokes of ordinary presses can reach several tens of times per minute. High-speed pressures can reach hundreds or even thousands of times per minute, and each press stroke is You may get a punch.

(2) Since the die guarantees the size and shape accuracy of the stamping part during stamping, and generally does not destroy the surface quality of the stamping part, the life of the die is generally longer, so the stamping quality is stable, the interchangeability is good, and it has “the same” Characteristics.

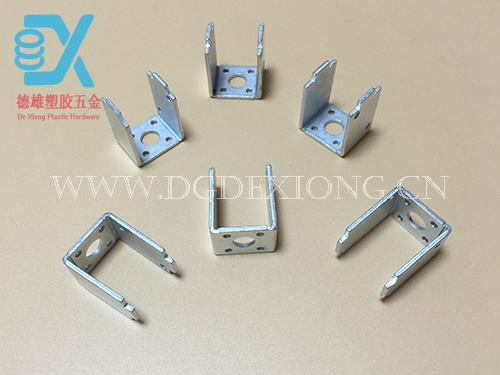

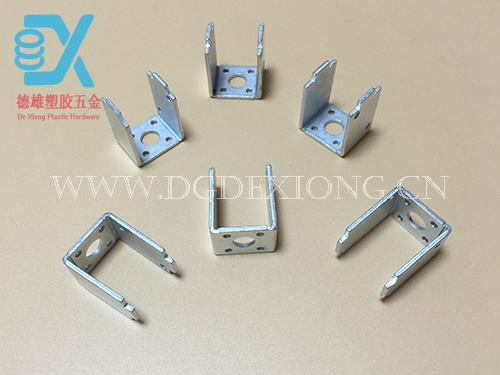

(3) Stamping can process parts with a wide range of sizes and shapes, such as stopwatches as small as clocks, as large as automobile longitudinal beams, coverings, etc., plus the cold deformation hardening effect of materials during stamping, the strength of stamping and The stiffness is high.

(4) Stamping generally does not generate scraps, material consumption is less, and no other heating equipment is required. Therefore, it is a saving material and energy-saving processing method, and the cost of stamping parts is low.

Press processing is the use of conventional or special press equipment power, so that the sheet material in the mold directly by the deformation force and deformation, so as to obtain a certain shape, size and performance of the production of parts of the technology. Sheets, moulds and equipment are the three elements of stamping. Stamping is a kind of metal cold deformation processing method. Therefore, it is called cold stamping or sheet stamping, referred to as stamping. It is one of the main methods of metal plastic processing (or pressure processing), and it is also affiliated with material forming engineering technology. In order to meet the requirements of shape, size, precision, batch, and raw material properties of stamped parts, various stamping methods are used in production. Summarized press processing can be divided into two major categories of separation processes and forming processes. 1. Separation process: It is the process of separating the stamping part and the sheet material along a certain contour line during the stamping process.

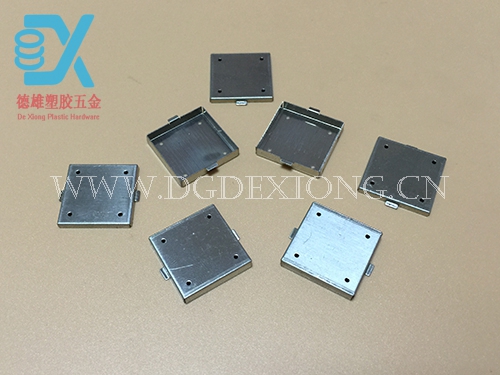

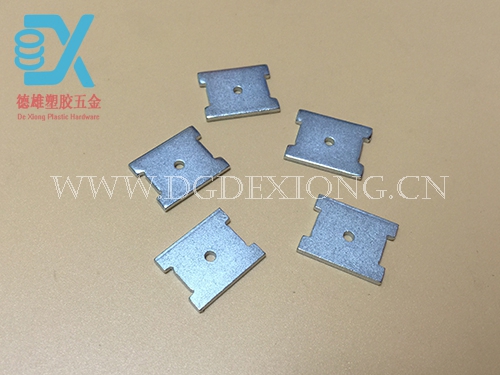

Fenggang Dexiong plastic hardware products specializes in metal stamping and mold design and manufacturing, with a full range of metal stamping, metal mold equipment, 16-250T punch, Taiwan precision grinding machine, milling machine; company independent research and development of metal mold design and production, precision metal parts processing, Precision metal products stamping production, precision automatic continuous stamping die, composite die, single die and so on. For customers design, drawing, proofing, open mold, stamping production through-train service. And provide product design before consulting services and mold making, product stamping, after-sales service, etc., to help customers solve the structural problems in production and timely amendments and improvements.

Dexiong Plastic Hardware Products17 years dedicated to the production and processing of metal stamping parts

Dexiong Plastic Hardware Products17 years dedicated to the production and processing of metal stamping parts  Dexiong Plastic Hardware Products17 years dedicated to the production and processing of metal stamping parts

Dexiong Plastic Hardware Products17 years dedicated to the production and processing of metal stamping parts