Dexiong Plastic Hardware Products17 years dedicated to the production and processing of metal stamping parts

Dexiong Plastic Hardware Products17 years dedicated to the production and processing of metal stamping parts  Dexiong Plastic Hardware Products17 years dedicated to the production and processing of metal stamping parts

Dexiong Plastic Hardware Products17 years dedicated to the production and processing of metal stamping parts

Phosphor Bronze (Phosphor Bronze) (Tin Bronze) (Tin Phosphor Bronze) Bronze is added Dephosphorization agent Phosphorus P content 0.03 ~ 0.35%, Tin content 5 ~ 8% .And other trace elements such as Fe, Zn , Fatigue resistance are good for electrical and mechanical materials, metal shrapnel manufacturers reliability is higher than the general copper alloy products. Bronze original refers to copper-tin alloy, after removing brass, copper other than copper are bronze and often bronze name The first crown to add the first name of the element. Tin bronze casting performance ﹑ anti-friction performance and good mechanical properties, suitable for the manufacture of bearings ﹑ ﹑ Worm gear. Lead bronze is a widely used bearing material for modern engines and grinding machines. Aluminum bronze high strength, good wear resistance and corrosion resistance, for casting high-load gear ﹑ bushings, marine propellers. Beryllium bronze and phosphorite, high elastic limit of copper, good electrical conductivity, suitable for the manufacture of precision springs and electrical contact elements, beryllium bronze is also used to make coal, oil depot and other non-sparking tools

history

However, objects made of copper are too soft, easily bent, and dull soon. Then people found that the tin into copper to make copper-tin alloy - bronze. Bronze devices are much easier to sinter and make than pure copper, harder than pure copper (if the hardness of tin is set to 5, then the hardness of the copper is 30 and the hardness of the bronze is 100 to 150). Historically this Period for the Bronze Age.

China's Warring States Period, "Zhou Li Kaogongji" summed up the experience of smelting bronze, bronze casting different objects on the use of different proportions of copper and tin: "golden six Qi (prescription) ) And tin in a home, that of the Zhong Ding Qi; five minutes of its gold and Tin in a, that the ax Qi Jin; quarter of its gold and tin in a home, that Gordon Ge Qi; third of its gold Tin in one, that the blade of the Qi; five points of its gold and tin in two, that cut off the arrow (arrow) Qi; Jin tin half, that the Kam (mirror) Sui (the use of mirror light to take fire) This shows that more than 3,000 years ago, our working people had realized that different proportions of bronze required performance and that the proportion of metal used to cast bronze should be different. Hardware shrapnel manufacturers.

Bronze, hard, fusible, well cast, stable in the air, did not lose its value, even in the Iron Age after the Bronze Age. For example, about 280 years BC, the bronze sun god stands at the port of Lot on Rhode Island in the Aegean Sea in Europe, reaching a height of 46 meters. The height of his fingers is higher than that of adults.

characteristic

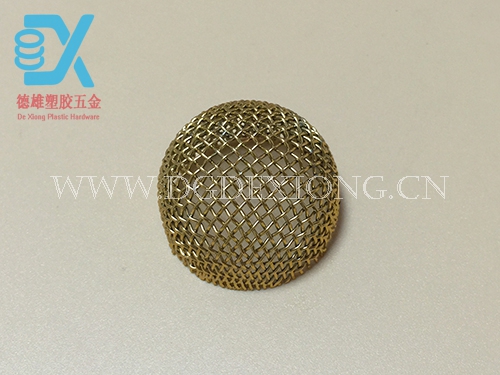

Tin phosphor bronze has a higher corrosion resistance, wear resistance, the impact does not occur when the spark. For medium-speed, heavy-duty bearings, the maximum working temperature of 250 ℃. With self-aligning, insensitive to deflection, the bearing capacity of uniform bearing capacity can be subject to radial load, self-lubricating maintenance-free features. Tin phosphor bronze is an alloy copper, with good electrical conductivity, easy to heat, to ensure safety while having a strong anti-fatigue. Phosphor bronze jack reed hardwired electrical structure, no rivet connection or frictionless contacts, to ensure good contact, good elasticity, dial a smooth. The alloy has excellent machinability and performance into the chip, can quickly shorten the processing time. Phosphor bronze as a master alloy is widely used in copper casting, solder and other fields, in the development of the national economy occupies an important place. Hardware shrapnel manufacturers